Products Guide

Vertical Leveler(Solder Coater)

- Solder levelers which are ideal for preprocessing of circuit boards.

HAL-211

|

1.Lead-free solder design

- Stabilization of solder temperature is realized by large capacity of the pipe heater and enlarged size of solder bath.

- Lead-free SUS316 is used for the material of solder bath to prevent corrosion of the solder bath.

- Increased air heater capacity stabilizes the set air temperature.

2.Highly reliable HS-651 structure for the driving section

- A structure similar to HS-651 is adopted as the driving section to ensure realibility.

3.Highly efficient & energy saving vertical type leveler

- Vertical type leveler is applied in order to save space and improve speed

|

|

HAL-311

|

1.Touch panel system

- All functions are centrally controlled.

- Pipe heater control allows minute control of solder temperature.

- Data are recorded and stored.

- Past data can be called up for reapplication.

- Data can be transferred to PC for accumulation and editing.

2.Lead-free exclusive design

- Increased solder pipe heater capacity stabilizes solder temperature (15kw→17kw)

- Increased solder bath capacity stabilizes solder temperature (15% larger than the conventional one.)

- Material of solder bath is changed to SUS316 as an anti-corrosion measure, preventing the corrosion of the bath by lead-free solder.

- Minute control of solder temperature stabilizes the set solder temperature.

3.Reliable driving section built upon excellent performance

- HS-601-D structure is adopted as the driving section to increase reliability.

- Adoption of this compatible structure enables stable supply of parts.

|

|

Solder for the leveler(Solder Coater)

| Product |

Alloy composition |

Capacity per box |

| LLS 219L |

Sn-Ag-Cu-X |

20kg |

| LLS 219AL |

Sn-Ag-X |

| LLS 220L |

Sn-Ag-Cu-X |

| LLS 220AL |

Sn-Ag-X |

| LLS 225L |

Sn-Ag-Cu-X |

| LLS 225AL |

Sn-Ag-X |

| LLS 227L |

Sn-Cu-X |

| LLS 227AL |

Sn-X |

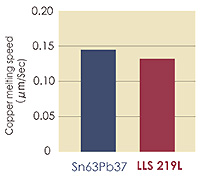

| LLS 219L

Copper corrosion test

|